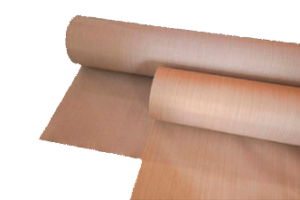

Basic Vitriflon®

Basic Vitriflon® PTFE coated fabrics are non-porous, PTFE coated and designed for a wide variety of applications; such as packaging, heat sealing and food industry.

These series could be a very good alternative due to its cost-effective performance.

Industrial Vitriflon® PTFE Coated Fabrics

Industrial Vitriflon® PTFE coated fabrics VTF-200 series, is for multiple use, non-porous and medium level of PTFE coating. Its most common applications are as a mold release agent for packaging, for heat-sealers and food industry. Industrial series are a good option due to its cost-effective performance.

Premium Vitriflon® PTFE Coated Fabrics

Premium Vitriflon® PTFE coated fabrics VTF-400, is used for different applications such as belting and as a mold release agent; it is also ideal for plastic bag sealing and for the food industry. Premium series are a good option due to its cost-effective performance, compared to the industrias series.

Standard Vitriflon® PTFE Coated Fabrics

Standard Vitriflon® PTFE coated fabrics (P.C.) VTF-300, is used for different applications; such as belting and as a mold release agent. It is also ideal for plastic bag sealing and for the food industry. Standard series are a good option due to its cost-effective performance compared to the premium series.

TR Vitriflon®

Vitriflón® Tear & Crease Resistant VTF-500 series are built with specialized coatings to increase tearing and tensil strength. These series are used for belting and they are mostly used in paper, food and pharmaceutical industries.

Anti-Static Vitriflon® PTFE Coated Fabrics

Vitriflon® PTFE coated fabrics (PC) VTF-600 Standard Series, is used for different applications such as belting and as a mold release agent; it is ideal for plastic bag sealing and food indutry. Standard series are an excellent alternative due to its cost, compared to the Premium series. It is mostly used in the apparel industry as conductive conveyor belts for fusing pressed machines.

Vitriflon® Characteristics

Mechanical

The fiberglass fabrics used as a support for PTFE give them great dimensional stability. The high tear resistance to breaking Vitriflon®️ PTFE coated fabrics are acquired thanks to fiberglass as a base. The possibilities of elongation are very low. The PTFE gives it its extraordinary anti-adherent properties and has the lowest coefficient of friction with respect to any solid substance.

Thermal

They do not become brittle, brittle, or soften after exposure to high temperatures up to 260 ° C (500 ° F), PTFE starts to decompose slowly and some fluoride-based detachments are produced. Vitriflon®️ PTFE coated fabrics can also be used at low temperatures down to -184 ° C (-300 ° F) for applications where flexibility is not required or 180 ° C (-112 ° F) for applications where flexibility is required.

Electrical

Vitriflon®️ fabrics have excellent electrical priorities, retain their unparalleled dielectric characteristics regardless of high or low temperatures. The range of dielectric rigidities is staggered between 250V and 1500V per thousandth of an inch (25.4 microns) of thickness according to the type of PTFE coated fabrics, according to the ASTM Short Time Meted method. Its power factor is less than 7 throughout the range reaching up to 100KC.

Chemical

In PTFE it is resistant to all solvents, acids, gasolines, weathering, humidity, mold and chemicals, except highly alkaline metals, fluorine at high temperatures and some halogen complexes. So Vitriflon®️ PTFE coated fabrics can be used in contact with corrosive products and in a corrosive environment.

These fabrics have excellent resistance to electric arcs; its tenacity is such that if the bow is maintained, no charring occurs at the point of attack of the bow. The surface resistivity is ohms/cm at 100% relative humidity and its resistivity is greater than ohms/cm even after immersion in water. Tetraflon® manufactures and designs belts for each application, seamless or with various types of splices and with different types of side guides such as snaps, eyelets, among others.

Technical Sheets

Other Fabrics

Tetraflon de México

Quality Policies

At Tetraflon Corp, S. de R. L. de C. V. we are totally committed to manufacturing and distributing products of the highest quality with efficacy and efficiency, complying with the requirements and applicable regulations of our clients and interested parties through the continuous improvement of the quality management system. .

Contact Us

Contact Information

Location

Eje 3 Norte #115,

Parque Industrial Toluca 2000

CP 50200, Toluca,

Estado de México

info@tetraflon.com

800 841 3846

Share your experience with Tetraflon®️ to continue improving our service! It only takes 2 minutes.