Teflon Characteristics

Thermostable polymer considered one of the most versatile within the thermoplastic materials causing one of its main characteristics is its high resistance to high temperatures.

Considered one of the most stable thermoplastic materials since at 260 ° C it preserves its properties without showing any decomposition, since its coefficient of thermal conductivity does not vary with changes in temperature, making it an ideal insulator.

PTFE is resistant to most chemical agents and solvents, thanks to which it is widely used both in construction and industry, it is attacked by alkaline metals by chlorine and fluorine trifluoride.

Resistant to atmospheric conditions and light since pieces of PTFE can be exposed for more than 20 years to extreme climatic conditions without having alterations in their properties.

Premium Vitriflon® PTFE Coated Fabrics

Premium Vitriflon® PTFE coated fabrics VTF-400, is used for different applications such as belting and as a mold release agent; it is also ideal for plastic bag sealing and for the food industry. Premium series are a good option due to its cost-effective performance, compared to the industrias series.

Polytetrafluoroethylene

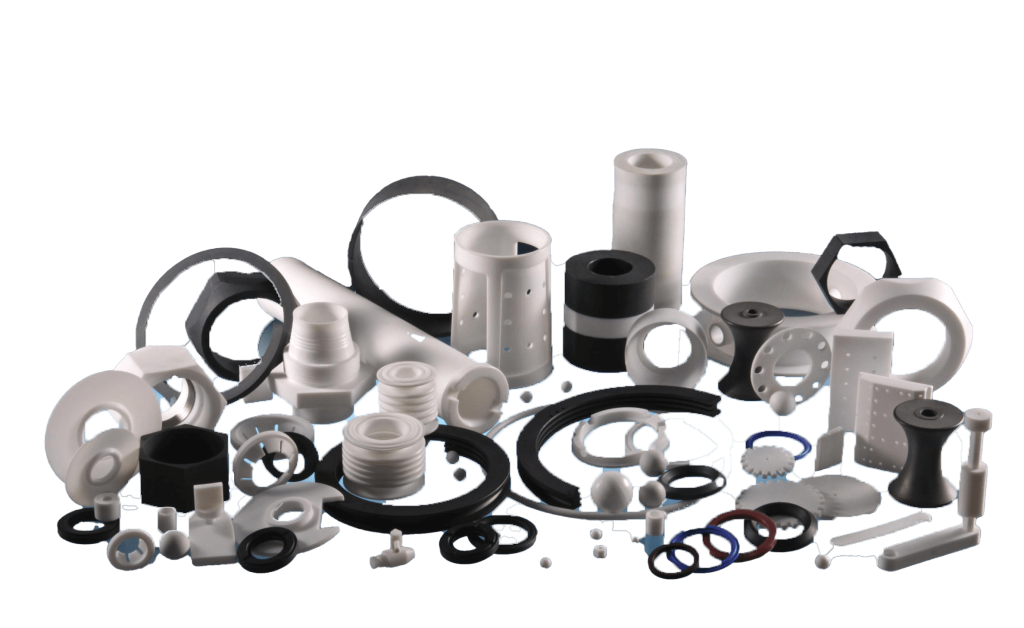

Due to its extraordinary non-stick properties, resistance to chemicals, extreme temperatures and for having the lowest coefficient of friction with respect to any solid substance, PTFE offers numerous applications in all types of industry, especially in the paper, chemical, oil, etc. electrical, nuclear, metallurgical, pharmaceutical, food, among others.

1938

Dr. Roy J. Plunkett, who was working with Freon gases, accidentally discovered that a sample he had left the night before in a pressure bottle, was polymerized into a waxy white material.

1939 – 1947

An analysis showed that it had outstanding properties and it was also very resistant to almost all chemicals and solvents; its surface was extremely slippery and as a result, nothing could stick on it. It was shown, as well, that this material didn’t absorb any moisture itself; sunlight could not degrade it and its melting point was at 620°F (342°C). However, the resin does not flow above the melting point, in contrast to common thermoplastics. As a result it could not be processes using the same method, so they developed a new one: compression molding to ambient conditions.

1948

DuPont made PTFE available for the market in 1948, when the first companies started to distribute this product that we currently process it in our company, based in Toluca.

Tetraflon de México

Quality Policies

At Tetraflon Corp, S. de R. L. de C. V. we are totally committed to manufacturing and distributing products of the highest quality with efficacy and efficiency, complying with the requirements and applicable regulations of our clients and interested parties through the continuous improvement of the quality management system. .

Contact Us

Contact Information

Location

Eje 3 Norte #115,

Parque Industrial Toluca 2000

CP 50200, Toluca,

Estado de México

info@tetraflon.com

800 841 3846

Share your experience with Tetraflon®️ to continue improving our service! It only takes 2 minutes.